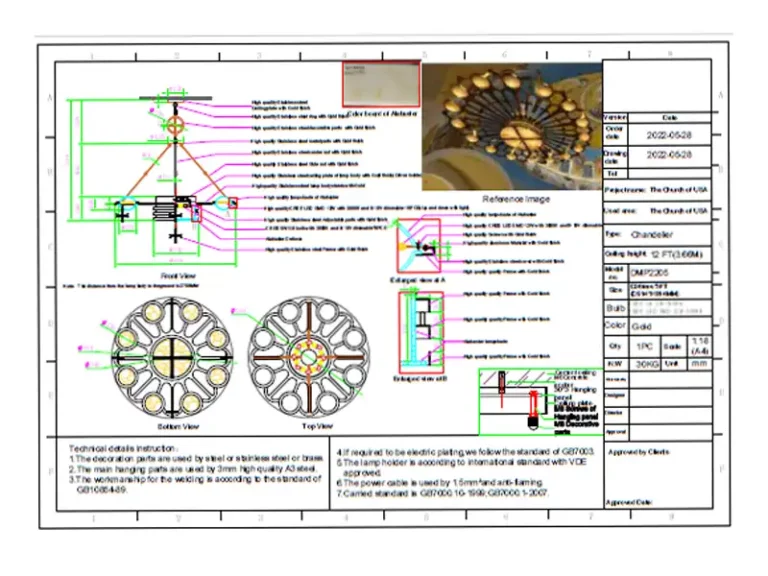

Project Introduction

In 2022, our company had the privilege of working on a unique project for a Christian church in the United States. The project involved the customization of a church chandelier, which would serve as a centerpiece in their place of worship. The client had specific requirements regarding the design, materials, brightness, and weather resistance of the chandelier.

High Quality Raw Materials

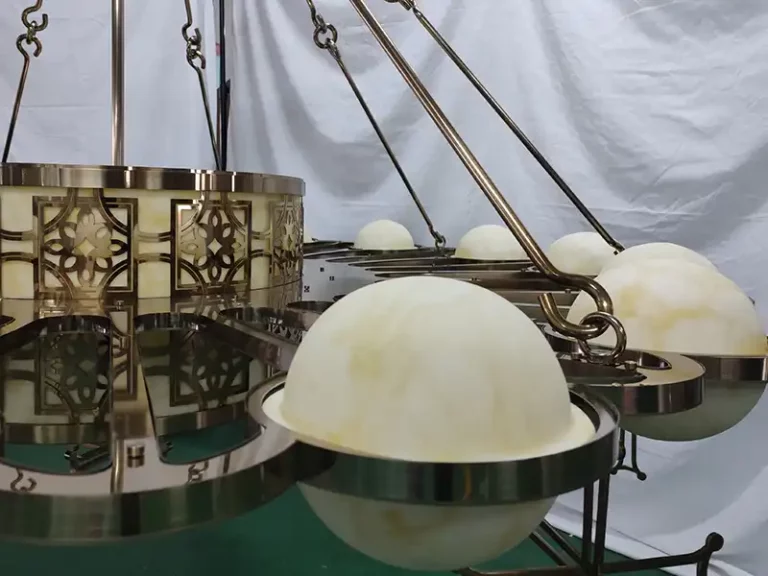

To make sure the chandelier lasts long and doesn’t rust, we went with stainless steel as the main material. It’s super tough and looks great, so it was perfect for a fixture that’ll be in the church for years to come.

For durability and weather resistance, the entire chandelier was constructed using stainless steel. To enhance the quality and longevity of the lamp, a special polymer coating was applied to the surface during production. This coating not only improved the chandelier’s ability to withstand weather conditions but also imparted a radiant shine to the overall texture of the lamp.

Illumination Solution

To meet the client’s request for a bright light source, we selected high-lumen LED lamp beads from the renowned brand CREE. These LED light sources were known for their exceptional brightness and energy efficiency, making them ideal for the church’s lighting needs. We customized three different sizes of LED light sources based on the predetermined dimensions of each chandelier.

Design

The chandelier was designed to exude elegance and spirituality. The body of the chandelier was crafted in golden and featured a textured spherical marble shade that resembled a planet. This aesthetic touch added a sense of grandeur and symbolism to the design.

Overcoming Heat Dissipation Challenges

Temperature outside the normal range

During the testing phase, an issue arose with the Small-sized chandelier regarding heat dissipation. Due to the limited space within the lampshade, the temperature within the chandelier reached undesirable levels. Resolving this challenge while preserving the chandelier's brightness was of paramount importance

Cooling solution

First, we added several small holes above the lampshade to increase air convection, facilitating better heat dissipation. These holes allowed for improved airflow, ensuring that the heat generated by the LED light sources could escape efficiently.Secondly, a heat sink was installed within the chandelier to dissipate heat effectively. This combination of measures ensured optimal performance and longevity of the LED light source.

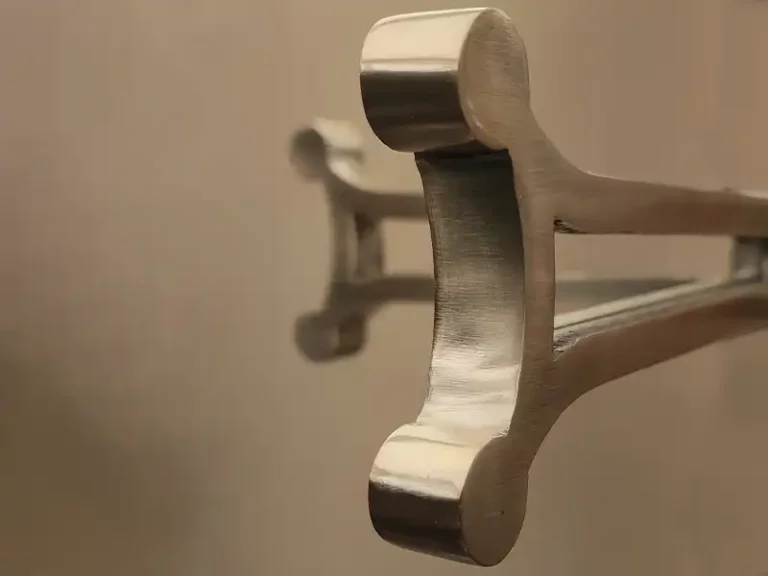

Mechanical Equipment Limitations

The 15mm diameter stainless steel side rod required specialized techniques to achieve the desired bend, as the existing mechanical equipment was unable to handle the bending process effectively. Through a combination of high-temperature calcination, manual forging, and mechanical bending, we were able to create a perfect arc for the side rod.

Raw Material Restrictions

Similarly, the 15mm thick cross required careful consideration. As this thickness of stainless steel plate was not readily available in the market, we employed a solution that involved welding two 8mm steel plates together. The welding process was followed by meticulous grinding to ensure a smooth surface, demanding precise control and persistence from our skilled employees..

In collaboration with the Christian church, we successfully customized a remarkable chandelier that aligned with their spiritual vision and met their specific requirements. The fusion of the gold body, textured marble shade resembling a planet, and Christian cross pendants created a truly awe-inspiring piece. By incorporating high-lumen LED lamp beads, heat dissipation solutions, and overcoming production challenges, we delivered a durable, weather-resistant, and brilliantly bright chandelier that would enhance the church’s ambiance for years to come.